The flexible stone production line represents a revolutionary advancement in the stone - processing industry, designed to meet the diverse and ever - changing demands of modern construction and decoration markets.

This production line is characterized by its high - flexibility design. It can process a wide variety of stone materials, including granite, marble, sandstone, and limestone. Whether it is large - scale blocks or small - sized stones, the production line can adjust its processing parameters accordingly, ensuring high - quality processing results for different stone types and sizes. For example, through advanced computer - controlled systems, the cutting, grinding, and polishing processes can be precisely customized to meet the specific requirements of different projects.

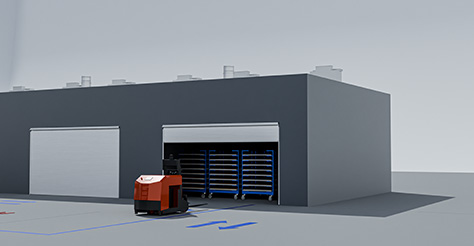

1.Feeding System

The feeding system of the flexible stone production line is designed to handle stones smoothly. It uses conveyor belts with adjustable speeds to ensure a continuous and stable supply of raw materials to the processing equipment. This not only improves production efficiency but also reduces the risk of material jams during the production process.

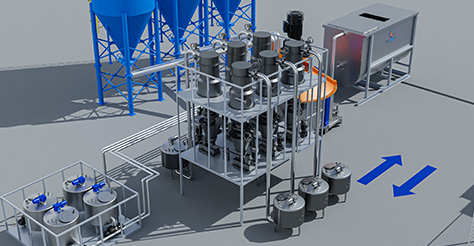

2.Cutting Equipment

Equipped with high - precision cutting machines, the production line can perform various cutting operations, such as straight - line cutting, curve cutting, and bevel cutting. These cutting machines are equipped with diamond - coated blades, which have excellent cutting performance and long service life. They can cut stones with different hardnesses accurately, meeting the complex shape requirements of modern architectural designs.

3.Grinding and Polishing Units

The grinding and polishing units are crucial for achieving the desired surface finish of the stone products. Multiple - stage grinding processes are carried out to gradually improve the flatness and smoothness of the stone surface. Then, high - speed polishing equipment is used to create a mirror - like finish or a matte finish according to customer needs.

4.Quality Control System

A sophisticated quality control system is integrated into the production line. Sensors and cameras are installed at various key points to monitor the production process in real - time. They can detect any defects or irregularities in the stone products, such as cracks, uneven surfaces, and incorrect dimensions. Once problems are detected, the system can automatically adjust the processing parameters or stop the production line for inspection and correction.

The products processed by the flexible stone production line have a wide range of applications. In the construction industry, they are used for building facades, interior floors, and wall decorations. The high - quality stone products can enhance the aesthetic and durable properties of buildings. In the field of landscape architecture, stone products are used to create garden paths, sculptures, and decorative walls, adding a natural and elegant touch to outdoor spaces.

In conclusion, the flexible stone production line, with its high - flexibility design, advanced components, and wide application areas, is an ideal choice for stone - processing enterprises aiming to improve production efficiency, product quality, and competitiveness in the market.